Lead-free into the future of building technology

| by Anika Faber

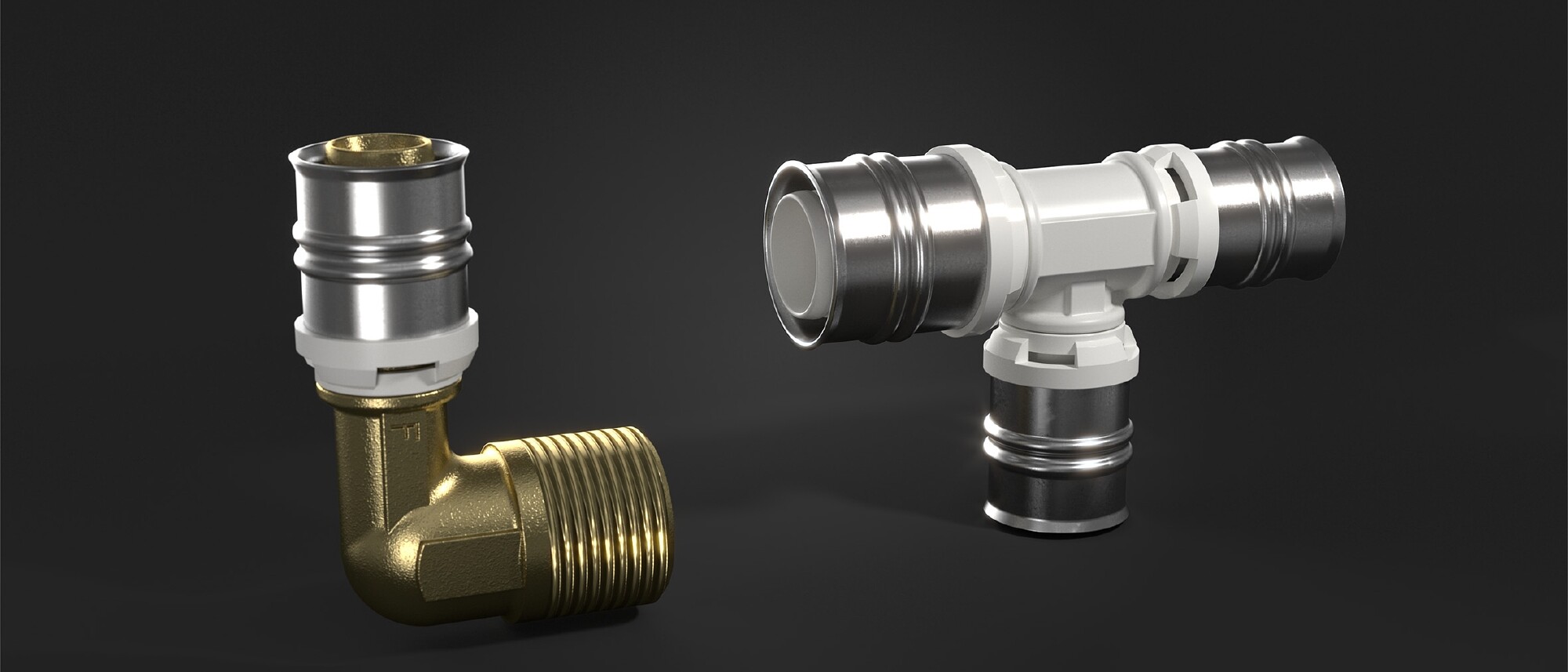

The future belongs to lead-free materials in building technology: They are hygienically flawless, harmless to health, more environmentally friendly and comply with European regulations, now and in the years to come. FRÄNKISCHE plays a pioneering role here: The specialist for building technology has been using lead-free brass for the fittings of its alpex F50 PROFI installation system for almost ten years, combined with the lead-free components made of the high-performance plastic polyphenylsulfone (PPSU) that were introduced in 2001.

Lead-free drinking water installations based on Europe-wide regulations to protect human health and the environment have been a topic in the industry for many years. Despite the information provided to date and successful material changes on the part of many manufacturers, there still seems to be a great need for information, especially in view of the noticeable tightening of the limit values up to a possible ban on lead-containing brass materials in the coming years. It is important for planners and installers to stay up to date at all times. This is the only way they can work in a legally compliant and technically up-to-date manner.

Harmful lead in drinking water

Lead in drinking water in particular can cause lasting damage to human health and the environment. Possible sources are lead pipes, but also lead-containing copper alloys, for example in pipe connectors or fittings. In order to better protect people and the environment, the EU Drinking Water Directive and the German Drinking Water Ordinance (TrinkwV) of 2001 have adopted the World Health Organization (WHO) guideline value that has been in place since 1993. With a transitional period that ended on December 1, 2013, the limit value for lead was significantly reduced from 25 to 10 micrograms per liter of water. Since then, the requirements for the quality of drinking water - both microbiological requirements and limit values for metals - must be met at every tapping point.

Multilayer composite pipes hygienically safe

Lead pipes had to be completely replaced as a result. However, pipes made of materials without heavy metals, such as certified plastics, are still considered hygienically safe. For lead-containing copper alloys in individual components such as fittings, the Federal Environment Agency (UBA) has published an overview of metal materials suitable for drinking water hygiene, which has since served as a basis for action for manufacturers, planners and installers.

Legally compliant material changeover

The clearly defined material specifications of the UBA give manufacturers security for their production process. FRÄNKISCHE has taken on a pioneering role here and has been relying on a lead-free brass material for its pipe connectors since 2013 - in addition to the high-performance plastic PPSU - which will also comply with all regulations in the coming years. Installers who use products and systems made from harmless, certified materials and work according to the generally recognized rules of technology are on the legally safe side when it comes to drinking water hygiene.

Stricter regulations for metallic materials

In January 2021, the EU made further adjustments to the European Drinking Water Directive: for example, it halved the permissible lead content from 10 to 5 micrograms per liter. EU member states have until spring 2023 to transpose the requirements of the Drinking Water Directive into national law. To ensure that everyone involved in Germany can comply with the new, lower lead values at the tapping points of the drinking water installation by the deadline, the Drinking Water Ordinance will be amended as a result.

Anyone using metallic materials for products with contact surfaces to drinking water must in future use materials that comply with European regulations, including a metal positive list. Only these materials will be permitted for the construction and maintenance of drinking water installations. Until the new European system comes into force, the guidelines and assessment principles of the Federal Environment Agency will continue to apply in Germany.

The effects on copper alloys

Some copper alloys that have a higher lead content in the Federal Environment Agency's metal assessment basis than will be permitted in future will not be able to reliably meet the new test value of the Drinking Water Directive and the Drinking Water Ordinance, which is yet to be amended: The lower limits for lead will probably restrict or even prevent the use of some copper alloys that are currently still permitted. For example, gunmetal containing lead (CC499K) may no longer be allowed to be used for the construction and maintenance of drinking water systems in the near future.

With regard to the lead content of materials for drinking water installations, other directives must also be observed, such as the REACH Regulation (EC) No. 1907/2006, an EU-wide chemicals regulation. Each of the currently applicable regulations is effective irrespective of the others, possibly also in the same area of application, and may also result in a ban on certain materials in the foreseeable future.

In order to better protect health and the environment, the framework conditions for drinking water installations have changed significantly in just a few years. Manufacturers of installation systems who want to continue to play a leading role in the future and in the long term must urgently consider how they can make their products and systems as lead-free as possible.

Lead-free: Installation system alpex F50 PROFI

Plastics is one of FRÄNKISCHE's core competencies in which the family-owned company has acquired extensive expertise over the decades. In order to counteract possible complications within the complex process and supply chains at an early stage, FRÄNKISCHE has been using materials such as the lead-free material CW724R or the space-proven high-performance plastic PPSU for years: Today, all parts of the alpex F50 PROFI installation system that come into contact with drinking water are completely lead-free. In recent years, the family-run company has also increasingly replaced components containing brass with PPSU fittings, which are corrosion-resistant, hygienically safe and environmentally friendly. The future-proof components give planners and installers legal certainty and the greatest possible freedom in their daily work. The building technology specialists want to continue along this path and gradually increase the proportion of PPSU components - in view of rising raw material prices and stricter international regulations, this is a future-oriented solution for the long-term and cost-effective protection of our drinking water.

![meta_9ac42098f17c76a1ddf37ef9eb7055b6[en_EN][title] meta_9ac42098f17c76a1ddf37ef9eb7055b6[en_EN][alt]](/assets/images/0/image-portrait-1d9gdtpr1xya1ym.png)